Efficient and Eco-Friendly: A Guide to Dry Ice Cleaning and Blasting

Dry ice cleaning is a state-of-the-art technology that leverages the unique properties of dry ice. This environmentally sustainable method provides an effective alternative to traditional cleaning processes like sandblasting, grit blasting, and soda blasting. Unlike these methods, dry ice blasting uses solid carbon dioxide (CO2) pellets, offering a myriad of benefits including no secondary waste, non-toxicity, and efficiency. In this comprehensive guide, we’ll explore what dry ice cleaning is, how it works, its benefits, the equipment required, cost considerations, safety precautions, and its efficacy on various contaminants like paint, rust, and mold.

What is Dry Ice Cleaning?

Dry ice blasting is an advanced surface preparation and cleaning method that uses recycled CO2 pellets. These pellets are accelerated through a pressurized air stream to clean surfaces at a supersonic speed. Upon impact, the dry ice sublimates (turns directly from solid to gas), lifting dirt and contaminants without abrasion or leaving residue. This process is non-conductive, non-flammable, chemical-free, and water-free, making it ideal for a variety of industrial applications.

Key Features:

- Non-Abrasive: Unlike sandblasting, dry ice does not damage the underlying surface.

- Non-Conductive: Safe for use on electrical equipment.

- Non-Flammable and Non-Toxic: Ensures safety and environmental compliance.

- No Secondary Waste: Sublimation of dry ice leaves no residues, eliminating cleanup.

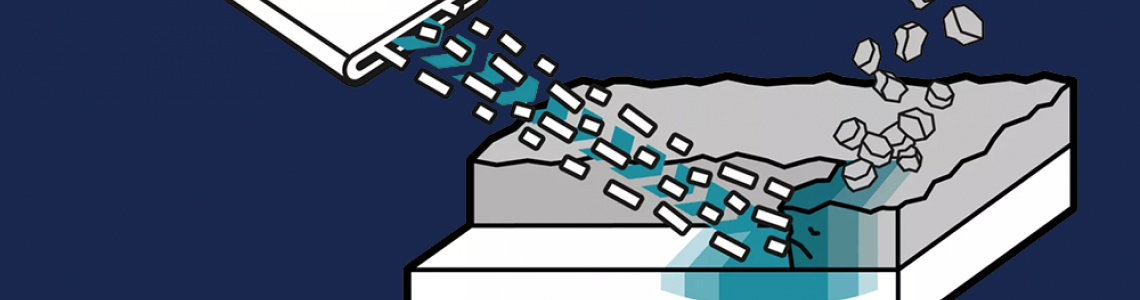

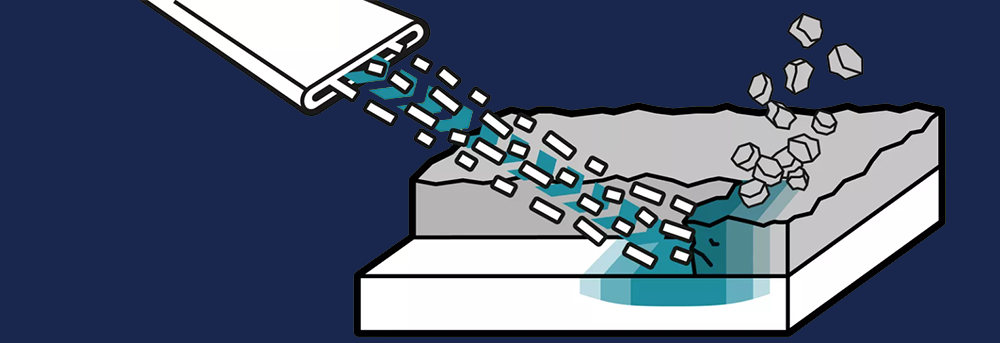

How Does Dry Ice Cleaning Work?

Dry ice blasting relies on three primary factors, summarized by the acronym ICE:

1. Impact (I): Dry ice pellets are propelled at supersonic speeds using compressed air, creating a kinetic effect that dislodges contaminants.

2. Cold (C): The extreme coldness of the dry ice (-109°F/-78.9°C) makes the contaminants brittle, breaking their bond with the substrate.

3. Expansion (E): Upon impact, dry ice sublimates and expands, facilitating the removal of contaminants.

This combination of kinetic energy, thermal shock, and rapid expansion allows dry ice cleaning to clean surfaces effectively and efficiently.

Benefits of Dry Ice Cleaning

Dry ice blasting offers numerous advantages over traditional cleaning methods:

- Enhanced Safety: Reduces the risk of exposure to toxic chemicals and harmful dust.

- Environmental Sustainability: Uses recycled CO2 and produces no secondary waste.

- Reduced Downtime: Equipment can often be cleaned in place without disassembly.

- Cost Efficiency: Minimizes labor costs and extends the lifespan of machinery.

- Superior Cleanliness: Achieves a higher level of cleanliness without the use of water or chemicals.

These benefits make dry ice cleaning a preferred choice in industries ranging from automotive to food processing and historical restoration.

Equipment Needed for Dry Ice Blasting

To start dry ice cleaning, a basic setup is required, which includes:

- Dry Ice Blasting Machine: The core component that includes the hopper, feeder, and blasting unit.

- Air Supply: Either plant air or a portable air compressor.

- Power Supply: To operate the blasting machine.

- Dry Ice: Pellets or blocks specifically designed for blasting.

Additional tools such as nozzles, hoses, and applicators are tailored to specific cleaning tasks, ensuring maximum efficiency.

Where to Buy Dry Ice

Dry ice is commonly available from industrial gas suppliers, welding supply companies, and local distributors. Options include one-time purchases or regular deliveries, with some suppliers providing services across extensive areas.

Cost of Dry Ice

The cost of dry ice varies depending on geographical location and market conditions. As a commodity, its price is subject to fluctuations influenced by supply and demand dynamics.

Safety Precautions

Safety is paramount when handling dry ice due to its extreme coldness and the potential for CO2 buildup in enclosed spaces. Key precautions include:

- Proper Ventilation: To prevent CO2 accumulation.

- Personal Protective Equipment (PPE): Gloves, safety glasses, and protective clothing are essential.

- Handling Instructions: Proper training on handling and storing dry ice safely.

Applications and Effectiveness

Removing Paint and Rust

While dry ice cleaning can remove loosely adhered paint and surface rust effectively, it may not be suitable for removing strongly bonded coatings or deep rust. Its effectiveness depends on the bond strength and type of coating.

Mold Remediation

Dry ice blasting is highly effective in removing mold, adhering to IAQA standards. It not only removes mold but also deodorizes the area, significantly reducing remediation time and labor costs.

General Cleaning

From machinery and electronic components to historical artifacts, dry ice cleaning can be adapted to a wide range of cleaning needs without damaging the substrate or leaving any residues.

Explore Our Dry Ice Cleaning Equipment

After learning about the benefits and techniques of dry ice cleaning and blasting, you might be considering incorporating this technology into your own operations. To meet this need, we offer a range of top-quality dry ice blasting machines available at BALTICDIAG. Our selection is designed to cater to various industrial requirements, ensuring that you find the perfect fit for your specific cleaning challenges.

Why Choose Our Equipment?

- Versatility: Our machines are suitable for a wide range of applications, from simple light cleaning to heavy-duty rust and paint removal.

- Efficiency: Designed for optimal performance, our dry ice blasters maximize cleaning efficiency, reducing downtime and labor costs.

- Environmental Sustainability: Embrace a cleaning solution that minimizes environmental impact, aligning with modern sustainability standards.

All our equipment is supported by comprehensive service and maintenance offerings to ensure your dry ice blasters remain in peak condition. For more details on our products and how they can enhance your cleaning operations, visit our website and explore our full range of dry ice cleaning solutions.

Conclusion

Dry ice cleaning and blasting represents a significant advancement in cleaning technology, providing a safe, efficient, and environmentally friendly alternative to traditional methods. With its ability to clean thoroughly without secondary waste or damage to equipment, dry ice cleaning and blasting is an excellent choice for many industrial, commercial, and preservation applications. Whether you are dealing with routine maintenance or specialized cleaning challenges, dry ice cleaning and blasting offers a compelling solution that meets the needs of modern industries.

This guide aims to serve as a starting point for those considering the adoption of dry ice cleaning, providing essential information to make informed decisions and optimize cleaning processes.

-150x150w.jpg)